Selection of cleaning equipment in feed machinery

Grid screener is the simplest cleaning equipment. It is only welded by several steel bars. The main function is to prevent large impurities such as clod, stone and rope into the inlet, and avoid blockage. Also, it can prevent the workers from falling into the inlet and protect the safety of workers. Grid screener is the first cleaning equipment, almost each feeding inlet should set it up, such as the main and auxiliary feeding inlet in the main workshop, the artificial feeding inlet of additives beside the batching scale.

The gap of grid screener should be determined according to different feeding inlets and different materials. For example, in main workshop, the grid screener gap of feeding inlet of corn and powder feed is about 30 millimeters. In the case of the corn feeding inlet in front of the vertical silo, the gap can be larger because of the required larger output. For the raw materials of cake and meal, the gap should be about 40 millimeters because of its poor dispersion.

The gap of grid screener should be determined according to different feeding inlets and different materials. For example, in main workshop, the grid screener gap of feeding inlet of corn and powder feed is about 30 millimeters. In the case of the corn feeding inlet in front of the vertical silo, the gap can be larger because of the required larger output. For the raw materials of cake and meal, the gap should be about 40 millimeters because of its poor dispersion.

The screener can be made of flat steel with thickness of 2 mm ~3 mm and width of 10 mm ~20 mm, or round steel with diameter of 10 mm. It should be fixed at the feeding inlet and ensure an inclination of 8 ~10 degrees, so that the materials in the bag can be poured out and the labor intensity can be reduced.

The cleaning sieve is the main equipment for cleaning and removing impurities in feed mills. Cylinder initial cleaning sieve, cone powder cleaning sieve and plane rotary vibrating sieve are commonly used.

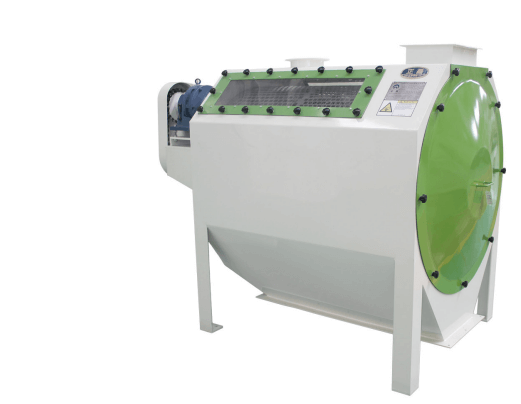

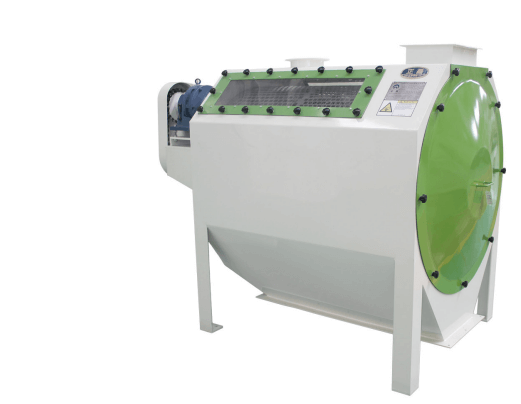

Cylinder initial cleaning sieve is mainly used to clean pellet materials such as corncob, hemp rope, cloth piece, stone, clod, straw, etc. It is not suitable for powder feed, because the dispersion of powder feed is worse than particle. It is easy to pile up and block in the feed chute, so that production cannot be carried out smoothly. The initial cleaning sieve has the characteristics of simple structure, small volume, large output, small power, convenient installation and easy maintenance, and can select the suitable sieve tube according to the nature of materials.

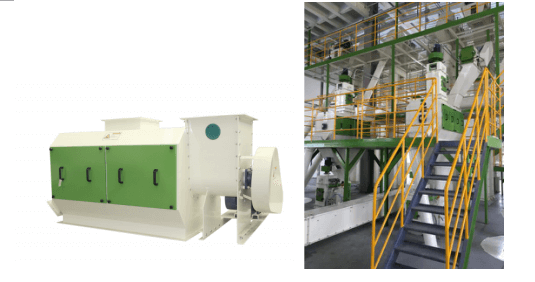

Cone powder cleaning sieve is mainly used for the cleaning of the powdery raw material in the feed plant, which can effectively remove the large impurities mixed in the powder feed and can break block powder. The cleaning sieve uses spiral forced feeding, so that the powder feed can be fed smoothly into the horizontal sieve tube to avoid blockage in the conveying process. But since there are radial spokes in the device, impurities such as rope head are easily entangled and not easy to be removed. In general, the model has advantages of compact structure, easy installation, high impurity removal efficiency, reliable and smooth operation, and convenient disassembling.

Cone powder cleaning sieve is mainly used for the cleaning of the powdery raw material in the feed plant, which can effectively remove the large impurities mixed in the powder feed and can break block powder. The cleaning sieve uses spiral forced feeding, so that the powder feed can be fed smoothly into the horizontal sieve tube to avoid blockage in the conveying process. But since there are radial spokes in the device, impurities such as rope head are easily entangled and not easy to be removed. In general, the model has advantages of compact structure, easy installation, high impurity removal efficiency, reliable and smooth operation, and convenient disassembling.

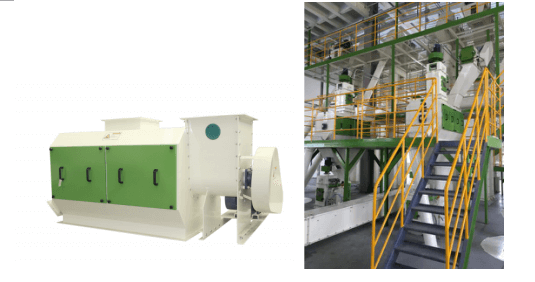

Plane rotary vibrating sieve can be used for cleaning pellet materials and powdery raw materials. Also, the larger impurities in the raw materials can be effectively removed. We can replace the sieve from the top, saving the space of sieve replacement, and the sieve is fixed with buckle, aensuring convenient operation. Compared with the first two kinds of equipment, it has strong adaptability to material, high impurity removal efficiency, but impurity outlet is small and sometimes it is not smooth. For the same amount of treatment, the power consumption and area are larger, the price is higher, the noise and vibration are easily produced.

Plane rotary vibrating sieve can be used for cleaning pellet materials and powdery raw materials. Also, the larger impurities in the raw materials can be effectively removed. We can replace the sieve from the top, saving the space of sieve replacement, and the sieve is fixed with buckle, aensuring convenient operation. Compared with the first two kinds of equipment, it has strong adaptability to material, high impurity removal efficiency, but impurity outlet is small and sometimes it is not smooth. For the same amount of treatment, the power consumption and area are larger, the price is higher, the noise and vibration are easily produced.

Magnetic separator can be divided into electromagnetic equipment and permanent magnet equipment according to different types of magnets. After electromagnetic equipment stop working, the iron impurity will drop into the material, causing inconvenience. Therefore, feed plant prefers to use permanent magnet equipment.

Magnetic separator can be divided into electromagnetic equipment and permanent magnet equipment according to different types of magnets. After electromagnetic equipment stop working, the iron impurity will drop into the material, causing inconvenience. Therefore, feed plant prefers to use permanent magnet equipment.

Source: Technical Advisor for Animal Husbandry

The screener can be made of flat steel with thickness of 2 mm ~3 mm and width of 10 mm ~20 mm, or round steel with diameter of 10 mm. It should be fixed at the feeding inlet and ensure an inclination of 8 ~10 degrees, so that the materials in the bag can be poured out and the labor intensity can be reduced.

The cleaning sieve is the main equipment for cleaning and removing impurities in feed mills. Cylinder initial cleaning sieve, cone powder cleaning sieve and plane rotary vibrating sieve are commonly used.

Cylinder initial cleaning sieve is mainly used to clean pellet materials such as corncob, hemp rope, cloth piece, stone, clod, straw, etc. It is not suitable for powder feed, because the dispersion of powder feed is worse than particle. It is easy to pile up and block in the feed chute, so that production cannot be carried out smoothly. The initial cleaning sieve has the characteristics of simple structure, small volume, large output, small power, convenient installation and easy maintenance, and can select the suitable sieve tube according to the nature of materials.

Source: Technical Advisor for Animal Husbandry